Project Geology and Metallurgy

Recent Exploration and Development

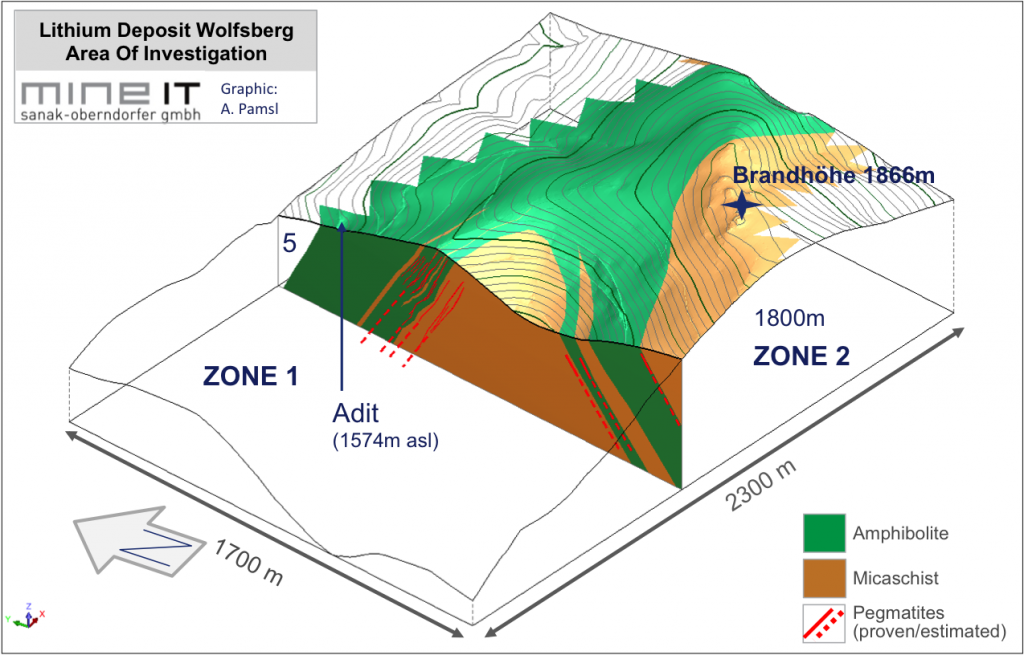

Project Topography

Historic Exploration and Development

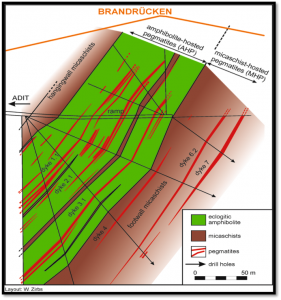

Section Through Deposit

Source: The spodumene depost at “Weinebene” Koralpe, Austria

by Dr.Göd, Mineralium Deposita 24, 270-278 (1989).

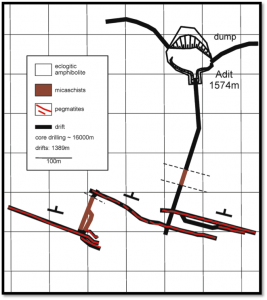

Mineworkings – Plain View

Source:

Company, prepared from Minerex data by Dr. Göd.

Metallurgy

- Mineral processing studies were undertaken for Minerex by the North Carolina State University. As a result of the testwork, using flotation and magnetic separation, spodumene concentrate with Li2O grades greater than 6% could be produced with spodumene recoveries of over 85%. Furthermore, ceramic grade feldspar and glass grade quartz were also recoverable. Mica concentrates were also considered a possible by-product. A pilot plant was set up which demonstrated that of all the mined and processed ore 74% was a saleable product.

- Since this work in the mid 1980’s there have been numerous advances in metallurgical technologies. Dorfner Anzaplan, Germany, were engaged to carry out metallurgical optimisation testwork. As the pegmatite veins at Wolfsberg are fairly narrow it can be expected that mining dilution could be significant. However, test work into laser sensor sorting has shown that in the treated size range +8 – 70mm, mining waste dilution can be effectively rejected maximising grade to the processing plant. The test work has confirmed that a flotation spodumene concentrate of 6% Li2O can readily be produced for sale or conversion to battery grade lithium carbonate and hydroxide. By products of feldspar and quartz were also produced which are suitable for ceramic and glass use in local industry. Test work on spodumene conversion using the commercially proven acid roast process demonstrated that battery grade lithium carbonate and lithium hydroxide can be readily produced from Wolfsberg spodumene concentrate.

Mining

- The Minerex study in the 1980’s concluded that open stoping and cut and fill were suitable mining methods and trial mining was undertaken. SRK Consultants were engaged to develop a conceptual mine plan for the declared resource with consideration given to how resource upgrades would impact the mine plan. This scoping level study concluded that long hole open stoping is the preferred mining method. Utilising only the measured and indicated resource leads to a mining rate of about 600,000tpa which after ore sorting to reject waste results in about 400,000tpa feed to the concentrator and production of just over 50,000tpa spodumene concentrate which converts to just over 7,000tpa lithium carbonate for a 13 year mine life. Preliminary economics indicated a production cost of US$5,000/tonne lithium carbonate. The study also indicated that the probable maximum mining rate was about 800,000tpa which would result in lithium carbonate production of 11,000tpa in full production years. However, increased resources are required to support increased production rates.

Environmental

- The project area is located in a commercial forest. The mining licence requires the submission of an operating plan to the Mining Authority before mining activities commence. This plan must also address environmental management. An environmental consultant, Umwelt Büro, is currently carrying out baseline studies.

Pre-Feasibility Study

- The Company successfully completed a positive pre-feasibility study (PFS) in Q2 2018.

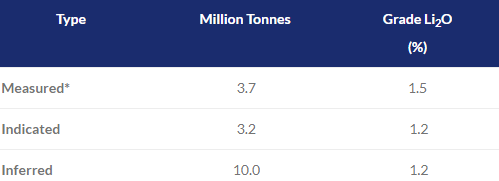

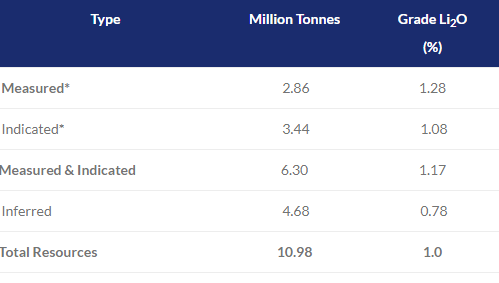

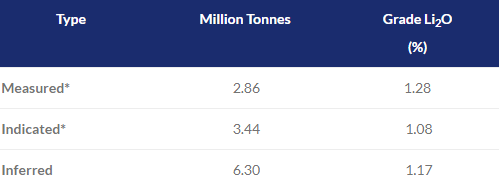

*Measured and Indicated resource at a cut-off grade of 0% Li2O as the veins will be mined contact to contact.

*Measured and Indicated resource at a cut-off grade of 0% Li2O as the veins will be mined contact to contact. *Measured and Indicated resource at a cut-off grade of 0% Li2O as the veins will be mined contact to contact.

*Measured and Indicated resource at a cut-off grade of 0% Li2O as the veins will be mined contact to contact.